Why Spray Foam is Great for Metal Buildings: A Beginner’s Guide

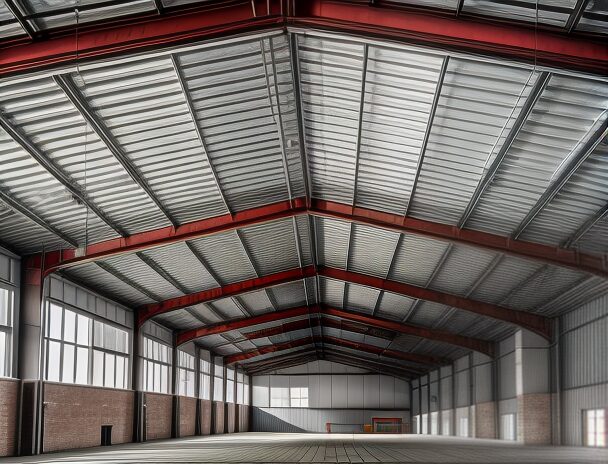

Metal buildings are incredibly versatile and popular for a variety of uses, from workshops and garages to barns and storage units. However, metal structures can have some unique challenges when it comes to insulation. Condensation, temperature control, and pests are just a few issues that can arise. Fortunately, spray foam insulation provides an excellent solution. In this guide, we’ll explore why spray foam is an ideal choice for metal buildings and how to use it effectively.

Setting Your Insulation Goals

The first step in any successful insulation project is to determine your goals. Ask yourself what you hope to achieve with insulation in your metal building. There are generally two primary reasons for insulating a metal building:

- **Condensation Control**: Metal buildings are prone to condensation, which can lead to moisture problems and damage over time. If your main goal is to prevent condensation, then applying one inch of closed-cell spray foam will typically suffice unless you are in the northern half of the US where 2″ is recommended.

- **Temperature Control**: If you want to maintain comfortable temperatures inside your metal building, whether for heating or cooling, you’ll need a bit more insulation. For optimal temperature control, it’s recommended to use two inches of spray foam on the walls and three inches on the roof.

Calculating Your Spray Foam Needs

To ensure you have enough spray foam for your project, you’ll need to do a bit of math. The amount of spray foam required is measured in board-feet. One board-foot covers one square foot at one inch thick. Here’s how to calculate your needs:

- **Measure the Walls**: Determine the square footage of all the walls you plan to insulate. Multiply this number by the desired thickness in inches.

- **Measure the Roof**: Measure the square footage of the roof and multiply by the desired thickness.

- **Total Board-Feet**: Add the total board-feet for the walls and roof. Then, add about 10% to account for waste.

- **Determine Kits Needed**: Divide the total board-feet by 600 (since a typical spray foam kit covers 600 board-feet). Round up to the nearest whole number to ensure you have enough material.

Preparing for a Successful Application

Preparation is key to a smooth and effective spray foam application. Here are some essential steps to follow:

- **Protect Surfaces**: Spray foam can be difficult to remove once it adheres to a surface. Cover anything you don’t want foam on, including floors, windows, and any equipment in the area. Also, make sure to protect yourself by wearing proper personal protective equipment (PPE), ensuring no skin or hair is exposed.

- **Clean Surfaces**: Metal sections may arrive with an oily residue to prevent sticking during shipping. This residue can prevent foam from adhering properly. If this is the case, clean these surfaces thoroughly with a recommended cleaner like mineral spirits. If not oily, broom clean is clean enough.

- **Temperature Control**: Ensure the surfaces you are spraying are between 65°F and 85°F for optimal adhesion and curing.

Spraying Technique Tips

Applying spray foam correctly can make a big difference in its effectiveness. Here are some tips for getting the best results:

- **Application Thickness**: Aim for a wet foam thickness of 1/3 inch, which will expand to one inch once cured.

- **Spraying Overhead**: When spraying the roof, remove the fan spray tip and use the mixing nozzle alone. Hold the nozzle closer to the surface and use a lighter trigger pull to avoid bouncing the foam off.

- **Even Coverage**: Move steadily and consistently to ensure even coverage without gaps.

Why Choose Spray Foam for Metal Buildings?

Spray foam insulation, particularly closed-cell spray foam, offers several advantages over traditional insulation materials like fiberglass and cellulose:

- **High R-Value**: Closed-cell spray foam has the highest R-value per inch, meaning it provides superior thermal resistance.

- **Air and Moisture Barrier**: The tightly packed cells in closed-cell foam prevent both air and moisture from passing through, which helps maintain a consistent indoor temperature and reduces the risk of mold growth.

- **Durability and Pest Resistance**: The dense nature of closed-cell spray foam deters rodents and insects, providing a longer-lasting and more hygienic insulation solution.

- **Ease of Application**: Spray foam can be applied quickly and efficiently, filling all gaps and irregular spaces that traditional insulation materials might miss.

Benefits of Insulating a Metal Building

Insulating your metal building offers several significant benefits:

- **Condensation Prevention**: Metal buildings are prone to condensation, which can lead to rust and other moisture-related issues. A layer of spray foam insulation helps to prevent this by creating a barrier between the warm, moist air inside and the cold metal walls, or in the south, hot metal walls clashing with cooler air conditioned air.

- **Energy Efficiency**: Insulating for temperature control helps keep the building warmer in the winter and cooler in the summer, reducing the need for additional heating and cooling. This can lead to significant energy savings over time.

- **Comfort**: Proper insulation makes the building more comfortable to work in, regardless of the outside temperature. This is especially important for workshops, garages, and any other spaces where people spend a lot of time.

- **Structural Integrity**: Spray foam can add a level of rigidity to the structure, helping to strengthen it.

- **Sound Deadening**: Whether it’s nearby road noise or the incessant pounding of a hard rain, foam does a fantastic job of stopping sound transfer. In the opposite direction, our customers using machinery and tools inside a shop have an easier time not bothering neighbors.

Step-by-Step Guide to Insulating a Metal Building with Spray Foam

Here’s a simplified step-by-step process to guide you through insulating your metal building with spray foam:

### 1. Plan Your Project

– Determine your insulation goals (condensation control vs. temperature control).

– Calculate the amount of spray foam needed using the method described above.

### 2. Prepare the Space

– Cover and protect any surfaces you don’t want to be sprayed.

– Clean the metal surfaces thoroughly to remove any oil or residue.

– Ensure the building’s temperature is within the recommended range (65°F-85°F).

### 3. Gather Your Equipment

– Personal Protective Equipment (PPE) including gloves, goggles, and coveralls.

– Spray foam kits (calculate the number needed based on your total board-feet).

– Cleaning supplies for any spills or mistakes.

### 4. Apply the Spray Foam

– Start with the walls, spraying in steady, even strokes.

– Move to the roof, adjusting your technique for overhead application.

– Aim for a wet thickness of 1/3 inch, which will expand to 1 inch.

### 5. Inspect and Touch Up

– Once the foam has cured, inspect for any gaps or thin spots.

– Apply additional foam as needed to ensure complete coverage.

### 6. Clean Up

– Carefully remove any protective coverings.

– Dispose of any waste material according to local regulations.

Conclusion

Spray foam insulation is an excellent choice for metal buildings, providing superior insulation, moisture control, and durability. By following the steps outlined in this guide, you can successfully insulate your metal building, creating a more comfortable, energy-efficient, and long-lasting space. Whether you’re working on a workshop, garage, or any other metal structure, spray foam offers a reliable and effective solution to meet your insulation needs.

Metal Buildings Spray Foam Project Guide

Read the metal building project guide for details and tips on application as well as recommended Foam it Green products for ultimate project success!

When in Doubt Contact Us!

Most projects are best suited to be attacked with closed cell foam. While it is initially more expensive, that increase in density will reward you with more structural stability, a higher R value, and moisture stopping power.

Still have questions about which foam might be best for your project? Just give us a call so we can have a project expert walk you through it – 1-833-FOAM-IT-G

.